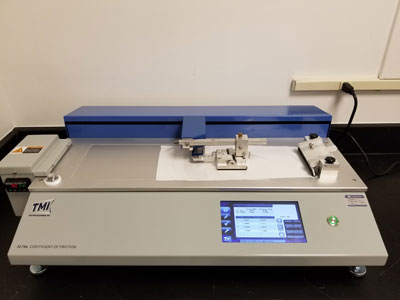

Coefficient Friction/Peel Tester

Applicable standards:

ASTM D 1894, ASTM D 3330, ASTM F 88, FINAT1, ISO 8295, PSTC 101, TAPPI T 549

Adhesive and Label Testing, Coating Testing, Corrugated Testing Equipment and Techniques, Film and Foil Testing, Ink and Printability Testing, Package Testing Equipment, Paper Testing & Equipment | Testing Machines Inc., Plastic Testing, Surface Property Testing

Coefficient Friction & peel tester PDF

Introduction

Testing Machines Inc., is globally recognized as the leading supplier of coefficient of friction instrumentation. Our NEW 32-76e coefficient of friction/peel tester uses advanced digital force signaling and high-speed data acquisition software to provide unmatched precision and repeatability in COF and peel testing.

Improved features include a color touchscreen display and intuitive software user interface for easy navigation and test method storage.

New peel testing capabilities include 180° peel and T-peel measurements.

Features

- High speed data collection and analysis for precise measurement of static COF with 500 readings during the first second

- Selection of test type-COF/Friction, T-Peel and 180° Peel

- Heated Platen Option, ambient to 162° C (325° F)

- Selectable units (COF, g, N, kg, lbs, and ounce)

- Selectable load cells from 5 to 100 N

- Automatically reports static and kinetic friction results after measurement

- Settable distance and time for static, kinetic and peel

- Peel results include average, minimum, maximum and SD of peel force

- Test storage including individual results up to 100 readings, average and standard deviation

- Direct drive arm with unique skid control.

- Sled-connecting mechanism ensures level pulling action

- New magnetic sled simplifies testing and throughput

- Direct output to PC-based GraphMasterProTM software providing friction/peel curve analysis, storage and reports

- Mini USB output for PC connection (GraphMasterPro compatible)

- USB output for data storage

Applications

Plastics film, packaging, paper, labels, coatings, cartons, adhesives, foils and printed materials

Standards

COF conforms to ASTM D 1894, ISO 8295, TAPPI T 549

Peel conforms to ASTM D 1876, ASTM F 88, ASTM D 3330, PSTC-101, FINAT1

Seal Strength/Peel Software

A comprehensive peel strength and heat seal application is included with the instrument. The operator can enter a variety of peel strength parameters designed to support most international peel test and heat seal international standards. Selectable units, pre-peel and peel distance settings allow flexible test method set-up and storage. Results include average, maximum, minimum and standard deviation of an individual peel test. The 32-76e also provides result and test curve data output to GraphMaster Plus, PC-based software for data collection, test curve analysis and results storage. A selection of test fixtures is available to meet most peel applications.

T-Peel Fixture is designed to measure the adhesive force of a heat seal or adhesive bonded substrate. The fixture attaches directly to the moving arm of the 32-76 Friction/Peel tester. A second clamp attaches directly to the instrument base. Included is one set (2) of test clamps, 30.5 mm (1.5 inch) wide, capacity is 100N.

Meets the following standards:

- ASTM D1876 T-Peel Test

- ASTM F 88 Seal Strength of Flexible Materials

180-Degree Peel Fixture measures the release strength of a label or peeling strength of an adhesive substrate. The fixture includes one set (2) of test clamps. One clamp is attached to the load cell with a clamping width of 50.8 mm (2.0 inch) wide, maximum capacity 100N. A second clamp is attached to the instrument base, maximum sample width is 125 mm (5 inch). With this fixture, release strength of labels and tapes can be performed. Typically, the label or tape is attached to a rigid backing.

Meets the following standards:

- PSTC-101 International Standard for Peel Adhesion of Pressure Sensitive Tape

- ASTM D 3330 Standard Test Method for Peel Adhesion of Pressure-Sensitive Tape

- FINAT1- Peel adhesion 180°

Meets the following standards:

|

Meets the following standards:

|

Heated Platen Option

During the manufacture and converting process of plastic films, the material is subjected to elevated temperatures. When using a heated platen, it is common that the heated surface for most plastic films will produce an increase in COF. Normally a temperature increase will influence the friction of the packaging material. However, not all films will react in the same way to an increase in temperature. To measure this behavior, the 32-76e Friction/Peel tester is available with an optional heated platen. The temperature can be set from ambient to 162° C (325° F). The heated platen option can easily be installed in the field on an existing 32-76e unit (Part # 32-76-08). The heated platen option meets ASTM D 1894 standards for friction testing at heated temperatures.

| GraphMasterProâ„¢ is a Windowsâ„¢ based software data collection program capable of providing test curve analysis, result data, data storage, exporting and printed reports. The software automatically captures individual test results and/or raw data. In addition to collecting data from instruments manufactured by Testing Machines Inc. and Buchel BV, GraphMasterProâ„¢ can be configured to communicate with instruments manufactured by other instrument suppliers. |

|

|

See PDF product data sheet for part numbers and descriptions.

Specifications

- Model: 32-76-00-0002

- Load Cells: Interchangeable load cells: 5N, 10N, 20N, 50N, and 100N

- Speed Range: 10-50 cm/min (4-20 in/per min)

- Travel Distance: 2.5 to 30.5 cm (1 to 12 in)

- Accuracy: +/- 0.1 % of load cell capacity

- Resolution: 0.001 gram based on 1000 gram/10N load cell (NOTE: Resolution will change depending on load cell in use)

- Available Sleds: 100 g – 1816 g (System software accepts variable sled weights) Please specify sled.

- Weight: 25 kg (55 lb)

- Instrument Size WxDxH: 515mm x 495mm x 508mm (20.3in x 19.5in x 20in)

- Power Input: 120/240 VAC 50/60 Hz

- Data Output: USB flash drive, USB ESC/POS printer, mini USB, GraphMasterProâ„¢

COF Standards

- TAPPI T549: Coefficients of Static and Kinetic Friction of Uncoated Writing and Printing Paper by use of the Horizontal Plane Method

- TAPPI T816: Coefficient of Static Friction of Corrugated and Solid Fiberboard (Horizontal Plane Method)

- ASTM D1894: Standard Test Method for Static and Kinetic Coefficients of Friction of Plastic Film and Sheeting

Peel Standards

- ASTM D 1876: Standard Test Method for Peel Resistance of Adhesives (T-Peel)

- ASTM D 3330: Standard Test Method for Peel Adhesion of Pressure-Sensitive (180° angle)

- ASTM F 88: Standard Test Method for Seal Strength of Flexible Barrier Materials

- PSTC-1016: Peel Adhesion of Pressure Sensitive Tape (180° angle)

- FINAT 1: FTM 1 Peel Adhesion (180°) at 300mm per minute

- EN 1939: Peel Adhesion Self Adhesive Tapes (180° angle)

Alternative Slide Angle Model

- 32-25-00: Incline Plane Coefficient of Friction Tester. Meets TAPPI T-815 and ASTM D202 with optional blocks.